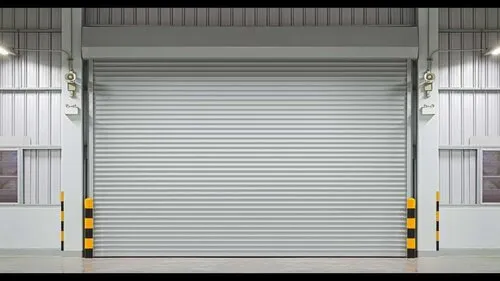

Rolling Shutter Manufacturers in Bangalore

Contact : +919448355485

Rolling Shutter Manufacturing

Introduction

Rolling shutters have become an essential component in various commercial and residential applications, offering security, insulation, and convenience. These shutters are particularly popular due to their ability to provide protection against theft, vandalism, and environmental elements. The process of manufacturing rolling shutters involves several critical steps, including design, material selection, production, and quality control.

Design and Material Selection

The first step in rolling shutter manufacturing is design. Manufacturers must understand the specific needs of their clients, including the size, style, and function of the shutter. Common designs include manual and motorized options, with motorized shutters being preferred for larger openings and enhanced convenience.

Material selection is crucial for the durability and effectiveness of the shutters. Rolling shutters can be made from various materials, including:

-

Aluminum: Lightweight and resistant to rust, aluminum is a popular choice for both commercial and residential applications. It can be anodized or painted to enhance its aesthetic appeal.

-

Steel: Known for its strength and security, steel shutters are often used in high-security environments such as warehouses and storefronts. They are more durable than aluminum but also heavier.

-

PVC and Other Composites: For applications where weight is a concern, PVC shutters provide a lightweight alternative. While not as strong as metal options, they offer decent security and insulation.

Production Process

Once the design and materials are finalized, the manufacturing process begins. This typically includes:

-

Cutting: Raw materials are cut to the required sizes using advanced cutting machinery. Precision is key, as the components must fit together seamlessly.

-

Forming: The shutter slats are formed into the desired shape. This may involve processes such as rolling or extruding, depending on the material used. For aluminum, extrusion is common, allowing for intricate designs.

-

Assembly: The cut and formed components are then assembled. This process can be manual or automated, depending on the scale of production. The assembly involves attaching the slats to the shutter tracks and ensuring all components function smoothly.

-

Finishing: Once assembled, the shutters undergo finishing processes such as painting, powder coating, or anodizing. This step not only enhances the appearance but also adds protective layers to resist corrosion and weathering.

Quality Control

Quality control is a critical aspect of rolling shutter manufacturing. Manufacturers conduct rigorous testing at various stages of production to ensure that the shutters meet industry standards and client specifications. This may involve checking for:

- Structural integrity

- Smooth operation

- Resistance to environmental factors

- Compliance with safety regulations

Any defective products are identified and rectified before reaching the market, ensuring customer satisfaction and minimizing returns.

Installation and After-Sales Support

Once manufactured, rolling shutters are packaged and shipped to clients. Professional installation is often recommended to ensure optimal performance and longevity. Many manufacturers also provide after-sales support, including maintenance services and warranties, to build long-term relationships with customers.

Conclusion

The manufacture of rolling shutters is a complex process that combines design, material science, and skilled craftsmanship. By focusing on quality, durability, and customer needs, manufacturers can produce rolling shutters that provide effective security and convenience for a wide range of applications. As the demand for robust and versatile security solutions continues to grow, the rolling shutter industry is poised for further innovation and development.